Description

Please note the terms of this offering were modified on October 7th, 2023. Please see the Additional Details Section below and the updated Confidential Private Placement Memorandum (PPM) for more complete information.

Summary

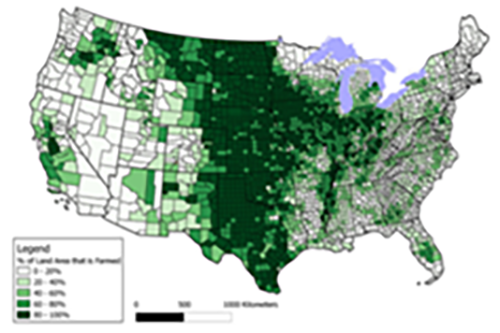

The City of TranquillityProject is on a 60-acre property in the town of Tranquillity in Fresno County, located in the central portion of the U.S. state of California. The project will have Biomass and Organic Fertilizer plants and Aerial Spraying Services operations. It will include a hotel with swimming pool and a small lake with a boating harbor, a church, recreational areas with baseball field, soccer and football fields, bike track, golf course and club house for the sports activities. The property includes an existing air strip.

The fertilizer plant will produce patented organic fertilizer with up to 78 chelated nano minerals. The fertilizer is sold under the names of NPK 75, Mineral-Groand Liquid TNT.

The existing runway lends itself to have an aerial spraying operation included in the project. Crop dusting planes can start from the property and service the farms and orchards surrounding the area.

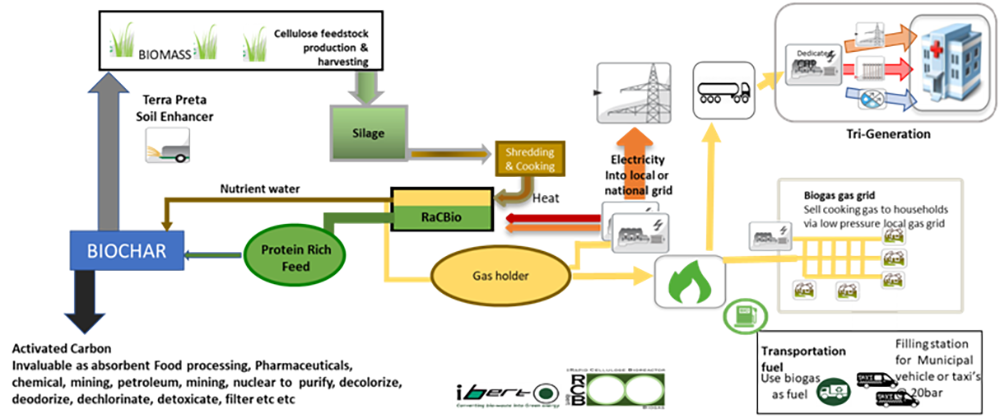

Tranquillity, located in a vast agricultural Valley, produces a large amount of biomass fuel and lend itself perfectly for a Biomass plant. The plant will produce, Electricity, RNG Gas, Biochar, Feeding Char and Terra Preta soil enhancer. Electricity and RNG can supply energy to the town and surrounding areas.

This is an opportunity to invest in a project in a proven growing region positioned to take advantage of market trends alongside a sponsor team whose experience encompasses the full value chain.

Region

Tranquillity is a census-designated place in Fresno County, California, United States. It is located 10 miles southeast of Mendota, at an elevation of 164 feet. The population was 799 at the 2010 census, down from 813 at the 2000 census. Tranquillity High School is the only high school in Town.

Fresno County, officially the County of Fresno, is a county located in the central portion of the U.S. state of California. As of the 2020 Census, the population was 1,008,654. The county seat is Fresno, the fifth-most populous city in California.Fresno County is the third largest producer with $8 billion in 2021, behind Kern and Tulare counties among California's top-producing agricultural counties. The county is between the Pacific Ocean and the Sierra Nevada Mountain range, creating a positive climate for many types of agricultural products.

Project

The current vision for the 60-acre property involves the development of Fertilizer and Biomass plants, Aerial Spraying services, an Aerial runway, Residential areas, Offices, Warehouses, Storage facilities, a hotel, and Recreational zones. Additionally, the property provides access to a Waterski Park adjacent to our premises. A railroad track along our property line will facilitate the connection of a railroad spur to the site.

The county of Fresno has already granted approval for an airport runway, along with biomass and fertilizer plants on an initial 6-acre parcel, which forms a substantial portion of the overall asset value. All future construction endeavors will follow a pre-leasing or pre-selling approach.

Opportunity Zone

No capital gains on investment

C-pace and Pace financing construction which a tax structure for 25% funding not as

deed of trust. Allowing us to reduce the down payment for sales. And reduce capital

need from the buyers financing and our financing on leased buildings.

Management

The Tranquility Group Inc team consists of the following highly experiencedindividuals:

Kevin Morton, is a seasoned professional with over 40 years of

experience in aerial spraying. He is currently serving as the President of the

aerial spraying division for Tortec Group Company. Throughout his career, he has

demonstrated an unwavering commitment to excellence and has played an instrumental

role in establishing Tortec Group as a leader in the industry.

In addition to his

vast experience in aerial spraying, Kevin has also overseen the construction of two

airports in the Fresno area specifically designed to provide aerial spraying

services. His expertise and leadership have been integral in expanding the company's

reach and enhancing its capabilities.

As Tortec Group continues to expand globally, Kevin will play a key role in leading the company's aerial spraying division and ensuring that it remains at the forefront of the industry. With his deep knowledge and experience, he is well-positioned to guide the division through the challenges and opportunities that lie ahead.

Kevin Morton is a seasoned professional with over 40 years of experience in aerial spraying with Mid Cal Aviation. He is currently serving as the President of the aerial spraying division for Mid Cal Aviation a subsidiary of Tortec Group Company. Throughout his career, he has demonstrated an unwavering commitment to excellence and has played an instrumental role in establishing Tortec Group as a leader in the industry.

In addition to his vast experience in aerial spraying, Kevin has also overseen the operations of two airports in the Fresno area specifically designed to provide aerial spraying services. His expertise and leadership have been integral in expanding the company's reach and enhancing its capabilities.

As Tortec Group continues to expand globally, Kevin will play a key role in leading the company's aerial spraying division and ensuring that it remains at the forefront of the industry. With his deep knowledge and experience, he is well-positioned to guide the division through the challenges and opportunities that lie ahead.

Darwin McKay, aleading agriculture executive, consultant,

innovator, educator, researcher, and industry influencer L. Darwin McKay leads the

advisory board for EquitasAssets. A seasoned businessman, he has 40+ years of

experience in the food science and agriculture sector.

Since 1980, McKay has served as President of The Turf Company, which has spearheaded

major applications of the genetics of turf grass in the U.S. Inland Pacific

Northwest and supports plant breeders and geneticists. Additionally, he is also the

Founder and President of High Desert Turf. One of The Turf Company’s solid sellers

is a proprietary blend called Xerilawn that benefits from low water use due to its

heat tolerance and deep rooting.

He is active with Turf Producers International and the American Sod Producers Association and currently sits on the board of directors for both groups. He is also a member of the Advisory Council of the Boise State University horticulture department and previously served on the board of directors for the Good Samaritan Hospital in Los Angeles, CA. Earlier in his career, he was named an Outstanding Vocational Agriculture Teacher by the American Vocational Association.

McKay earned a B.S. in Agricultural Education and a M.S in Agricultural Education and Food Science at the University of Idaho. He was commissioned to the U.S. Army while a student at the university and subsequently served on active duty and in the reserves for 20+ years.

Zackary Andrade, President of Spinaca Farms, Inc. with a

demonstrated history of working in the farming industry. Skilled in Operations

Management, Operating Budgets, Sanitation, Management, and Continuous Improvement.

Strong business development professional, consistently seeking to increase value for

customers, shareholders, employees and supplier partners. Before becoming the

President of Spinaca Farms, he was the Operations Director of the company,

responsible to manage the daily activities accomplished versus the budgeted needs of

the business to ensure the customers receive the highest quality product on time, as

promised

He has a Bachelor of Science (B.S.) focused in Agricultural Business and Management,

minor in Viticulture & Wine Marketing from California Polytechnic State

University-San Luis Obispo. Experienced President with a demonstrated history of

working in the farming industry. Skilled in Operations Management, Operating

Budgets, Sanitation, Management, and Continuous Improvement. Strong business

development professional with a Bachelor of Science (B.S.) focused in Agricultural

Business and Management, minor in Viticulture & Wine Marketing from California

Polytechnic State University-San Luis Obispo.

Philip Neilson is an attorney and serves as Veritas Group Limited

and Tranquility

Group Inc., Corporate Compliance Officer. He began his career working at the U.S.

Federal Bureau of Investigation for 23 years as a Special Agent and Legal Counsel.

Upon his retirement in January 2012, he opened Neilson Law Office with a focus on

the general practice of law and helping those in need.

Philip is licensed to practice in the State of Mississippi, The Supreme Court of

Mississippi, the United States District Court for Northern and Southern Mississippi,

and the United States Court of Appeals Fifth Circuit. He is a Member of the

Mississippi Bar Association, the Lafayette County Mississippi Bar, the Federal

Bureau of Investigation Agents Association, the Society of Former Special Agents of

the Federal Bureau of Investigation, Inc., and the Federal Law Enforcement Officers

Association.

Stephen Smoot has been in International Business Development since

1982. He negotiated over USD 900,000,000 in international contracts, including a USD

490,000,000 manufacturing agreement with the China Great Wall Industry Corporation,

the commercial arm of the Ministry of Aerospace and Astronautics of China.He managed

numerous international technology development and transfer agreements with the

Chinese governmental companies.He was a Marketing consultant for Golden West

Artemia, primarily targeting the Southeast Asia market.

Stephen directed the formation of numerous Joint Venture companies in USA, Mexico,

Afghanistan, Middle East, China and former Soviet republics. He is a specialist in

offshore corporate asset protection and trust management for non-US Persons and

directed international corporate mergers and acquisitions for US public companies.

He started out with his own business in Real Estate; opened the Denver, Colorado office of Marcus & Millichap, a national commercial brokerage firm specializing in the sale and acquisition of income-producing properties; developed 1,200 acres of sub-divisions in central Utah; owned and operated apartment complexes, mobile home park and ranch properties.

He also worked in Oil & gas leasing, exploration and production of oil & gas wells in Montana & Texas.

Stephen is currently President & CEO Veritas Group Limited.

Why We Chose This Investment

- Opportunity to invest in a unique project in a premium agricultural Support area.

- Experienced Sponsor team that brings decades of expertise in agricultural management.

Additional Details

Minimum Subscription Requirement: $100,000

Maximum Subscription Amount: $10,000,000

Termination Date: December 31, 2023

Risk Factors

Please refer to the PPM for the full list of risk factors.

Geographic Concentration

The Project is in one agricultural region of

California. This exposes the Company to greater economic risks than if it owned a

more geographically diverse asset base. As a result of the geographic concentration

of farmland, the Company is particularly susceptible to developments or conditions

in this geographic area, including adverse weather conditions (such as drought,

fire, windstorms, tornados, floods, hail and temperature extremes), earthquakes,

transportation conditions, crop disease, pests and other adverse growing conditions,

and unfavorable or uncertain political, economic, business or regulatory conditions

(such as changes in price supports, subsidies and environmental regulations). Any

such developments or conditions could materially adversely affect the value of the

Project, which could materially adversely affect the Company’s financial condition,

results of operations, cash flow and amounts it is able to distribute to Members.

and LLC Agreementfor additional information. The updated Private Placement Memorandum is available in theDocumentstab to be viewed or downloaded. The PPM and offering descriptions should be read carefully to fully understand the objectives, risk factors, charges, and expenses of an investment.

Disclosures-Nick

Securities offered by Equitas Assets.

Alternative asset investing is speculative and involves a high degree of risk, including complete loss of principal and are not suitable for all investors. The PPM contains a complete list of all Risk Factors and should be read carefully before investing. There is no assurance any investment will achieve its objective. Alternative investments are illiquid, not listed on an exchange, and not a short-term investment. Distributions are not guaranteed. Offering represents interest in a newly formed entity. Changes in tax law may adversely affect offerings. This offering is a private offering and is not registered under the Securities Act or under any state securities laws or the securities laws of any other jurisdiction.

These images depict the farm and the commodities grown there. Note that Investors are purchasing shares in an entity that will purchase this farm but are not purchasing actual acreage of the farm directly. Farmland investments are also subject to additional risks including volatility in commodity prices, weather events or disease that could damage crops and many other operational factors.

Please see additional risk factors and in the Issuer Document Package for a discussion of additional risks. The above presentation is based upon information supplied by the seller and others, and some images shown may be used for representative purposes and may not have been taken on location at the subject property. While Equitas Assets performs extensive due diligence on the offerings on our Site, certain of the information presented in each offering may have been provided by third party sources. Therefore, Equitas Assets and its respective affiliates, officers, directors or representatives (the "AT Parties") hereby advise you that while all such third-party information contained herein has been provided by to us from sources deemed reliable, we cannot guarantee its accuracy. The AT Parties further make no representations as to the accuracy or completeness of any such information and undertake no obligation now or in the future to update or correct this presentation or any information contained herein.

Products – Organic Nano Fertilizer

How big is the Fertilizer industry? The global fertilizer market amounted to more than 193 billion U.S. dollars in 2021, an increase of roughly 12 percent in comparison with the previous year. However, the fertilizer industry suffers from two gaping problems: (1) The prevailing fertilizers in the world consisting of chemically based Nitrogen, Potassium and Phosphate (“NPK”) are known pollutants of ground water, soil depleters, and a major cause of algae blooms endangering aquatic life throughout the vast expanse of waterways. (2) There is a severe shortage of NPK as a result of world events, currently and for the foreseeable future, which has led to the potential of food shortages and starvation in the more vulnerable parts of the world.

Equitas Assets is a distributor for Mineral-Gro®, a “Climate Smart” liquid fertilizer containing nano-sized trace minerals and micronutrients that helps grow food and restores soil over time. Mineral-Gro®is more than 50% less expensive than prevailing NPK fertilizers, saving cash strapped farmers under massive financial strainMineral-Gro®eliminates the negative environmental effects of NPK, and produces larger, healthier, more disease resistant plants producing greater harvests and a shorter growing cycle.

Mineral-Gro® utilizes a proven USA patented technology to nano-size natural and pre-chelated trace minerals from mineral rich deposits. When used, the technology results in restored damaged soils, increased water retention (resulting in reduced water usage), reduced need for pesticides and traditional fertilizers, increased plant health and productivity and shortened growing times.

Mineral-Gro® is a liquid concentrate containing up to 78 chelated natural trace minerals, combined with additional macro and micronutrients - averaging from 100 to 900 nanometers in size. Mineral-Gro® delivers unprecedented availability of nutrients to the plants; can be used both in foliar spray and soil applications; and is a “Climate Smart” product that does not harm Mother Earth or our natural environment.

Purpose: To expand distribution and increase supply chain resilience within the agricultural fertilizer and nutrient management sector, in connection with the production of agricultural commodities worldwide.

Goal: To rapidly expand the distribution of commercially available fertilizer worldwide in order to provide farmers more local access to natural, climate smart fertilizer alternatives for producing agricultural commodities that reduce the impact of climate change.

Objective 1:Increase the production and use of climate smart, sustainable, and innovative nano micronutrient fertilizer solutions that reduce water usage, pesticides, and fertilizer requirements while restoring soils through organic solutions by 10,000,000 acres in 2023 and 50,000,000 acres per year thereafter.

Objective 2: Create a compliant, independent, and successful fertilizer business that generates ongoing employment, production of high-quality fertilizer, and meets all compliance requirements.

- Is a liquid concentrate containing up to 78 chelated natural trace minerals, combined with additional macro and micronutrients - averaging from 100 to 900 nanometers manufactured from natural and chelated trace minerals from mineral rich deposits located in the US and in Eastern Europe.

- Utilizes a proprietary technology and equipment (“Mineral-Gro®equipment”) which can produce 275-gallon plastic totes derived from micron-sized, pre-chelated Montmorillonite trace minerals (“Mineral Powder”) provided by Mineral-Gro®to the production facilities.

- Is a natural climate safe solution that results in almost zero water waste and very little solid waste and no harmful by-products during production compared to NPK chemicals manufactured from petroleum which require thousands of gallons of water and produce harmful by-products.

- Costs significantly less per acre than synthetic and other organic alternatives.

- Requires significantly fewer applications per growing season (3).

- Can be applied as a foliar spray or directly to the soil.

- Has much broader coverage per acre (1 gallon per acre) than other types of synthetic fertilizer.

- Can fully replace NPK as a fertilizer solution or can be used to reduce NPK applications.

- It actually rebuilds the soil over time by stimulating the growth of naturally occurring biologics (microbes) in the soil that reduces the need for pesticides, reduces water usage, shortens the growing season and increases plant growth over time.

- Has a proven increase in crop productivity of 50% or more based on research done by the renowned Pryanishnikov Institute of Russia.

- Provides a complete solution to the current worldwide agricultural and humanitarian crisis.

Verification

Demonstrated track record of performance of technologies

The performance of the patented Mineral-Gro®has been tested by farmers in the U.S. in 2020 and 2021 and researched by the renowned Pryanishnikov Institute of Russia in 2021/2022. U.S. farmers anecdotally report that Mineral-Gro®resulted in increases of crop production of up to 50%, a shortened growing season (enabling farmers to get in an extra crop), reduced use of water and pesticides.

The research conducted by the Pryanishnikov Institute on spring wheat and spring barley was conducted in the soil-climatic zone and venue: turf-podzolic heavy loamy soil, 1st agroclimatic zone on the experimental fields of the Federal State Budgetary Institution "VNII of Agrochemistry" in the Moscow region, Domodedovo micro-district. Barybino. The Institute compared Mineral-Gro®to a control crop using no fertilizer, the second crop comparison was to traditional NPK fertilizer.

The Pryanishnikov Institute determined the following from their tests: “[Mineral-Gro®] triggers and activates germination initiation mechanisms in all treatments [wheat and peas]. Plants respond to exogenous exposure to Mineral-Gro®, changing the physiological and biochemical status - increasing the synthesis of chlorophyll pigments and reducing the intensity of oxidative processes in the body, which helps optimize growth function, provides an earlier start of photosynthesis, which in turn contributes to better rooting, development of the primary root system, better use of soil moisture."

Palomar Labs study of the use of Mineral-Gro®on Cannabis conclusions:

- Mineral-Gro®realized a significant overall increase in yield at the 4 oz/gallon treatment rate

- Yield: Flower size and yield increased with the treated plants increased by 18%.

- Flower Size: Bigs increased by 17.88%

- Potency: Values did not change from the treated to untreated samples.

- Terpene: Concentration from the control to the treated samples increased by 9.75%

- Nutrition Stability: The variance in essential nutrient concentrations were limited with treated plants vs. untreated.

Cost Comparison Benefits:

This table provides a cost analysis of the use of synthetic fertilizers. Based on the table, the average cost of fertilizer per acre for corn is $247 and for Soybeans it is $110. Potatoes require about $1,800 per acre on average. Compared to synthetic fertilizers, Mineral-Gro®costs $100/acre for corn with 4 applications and $50 for soybeans with 2 applications required. For potatoes, Mineral-Gro®is $200/acre, without the harm caused by the high concentrations of under-utilized nitrogen, resulting in green-house gas emissions from nitrous oxide and harms through impacts on water-based ecosystems. Differences: Mineral-Gro®is 40% of the cost of synthetic fertilizers for Corn, 45% of the cost of synthetic fertilizers for soybeans, and 11% of the cost of synthetic fertilizers for potatoes. The cost comparison alone is enough to warrant adoption as a total replacement or a partial replacement of traditional synthetic fertilizers.

Table 1. Fertilizer Costs for Corn and Soybeans Using Fertilizer Prices in September 2021 and September 2022

| Requirments* |

Prices on 9/23/2021"

Prices

Costs

|

Prices on 9/23/2021"

Prices

Costs

|

Change |

|---|---|---|---|

|

Panel A. Corn*

ibs/acre

|

S/ton

S/acre

|

S/ton

S/acre

|

S/acre |

|

Anhydrous Ammonia®

170

|

788

67

|

1,318

112

|

45 |

|

DAP*

177

|

742

66

|

947

84

|

18 |

|

Potash’*

88

|

659

29

|

857

38

|

9 |

|

Nitrogen stabilizer

|

13

|

13

|

|

|

Total Fertilizer Costs

|

$175

|

$247

|

$72 |

|

Panel B. Soybeans" DAP”

ibs/acre

|

S/ton

S/acre

|

S/ton

S/acre

|

S/acre |

|

DAP*

111

|

742

41

|

947

53

|

12 |

|

Potash’*

133

|

657

44

|

857

57

|

13 |

|

Total Fertilizer Costs

|

$85

|

$110

|

$25 |

- Fer rear te are b&b don University of Illinois recommendations.

- Taken from the September 23. 2021 M//inoisProduction Cost Report. Agricultural Marketing Service, USDA.

- Taken from the September 22. 2021 M//inoisProduction Cost Report. Agricultural Marketing Service, USDA.

- Based on an expected corn yield of 220 Dushels per acre.

- Based on Maximum Return to Nitrogen (MRTN) rates for central tilincis for corn-following-soybeans (see Corn Nitrogen Rate Calculator at nttp://cnrc.agron.iastate.edu). Given prevailing prices. the MRTN anhydrous ammonia rate is 202 pounds per acre. For calculation of costs. the MRTN rates are reduced by 32 pounds to account for the nitrogen in DAP (OAP is 28% nitrogen, 32 = 177 pounds of DAP x .18).

- Prosphate requirements are .37 pounds per bushel of expected corn yield. OAP is 46% phosphate.

- K20 requirement is .24pounds of expected corn yield. Potash’s analysis is 0-0-GO

- Based on an expected soybean yield of GSbushels per acre.

- Phosphate requirements are 24 pounds per bushel of expected corn yield. DAP is 46% phosphate.

- K20 requirement is 1.17 of expected soybean yield. Potash analysis is 0-0-GO.

Market Impact and Opportunities

a) Adequacy, plan and mechanisms for input procurement

Mineral-Gro® is made from mineral rich deposits of chelated trace minerals in the US

and Eastern Europe. The deposits contain up to 78 active chelated trace minerals.

The minerals are first micronized into a powder.

The micronized mineral powder is then taken through a patented wet process where it

is nano-sized and put into a concentrated liquid form and shipped to distributors in

275-gallon totes.

Mineral-Gro® is able to deliver the mineral powder to wet plants as they expand to

process to liquid concentrate in 275-gallon totes. It may be that some shipments are

handled by rail (available) depending on the needs of distributors. The cost of a

driver and operation of the truck are included in the financial analysis for the

project.

b) Current and anticipated number of agricultural producersbenefiting from the project

The unique characteristics of the pre-chelated nano-sized Montmorillonite 78 trace minerals in the means they can be absorbed directly through foliar application more efficiently than traditional fertilizer chemicals. Mineral-Gro® absorption rate is 95% compared to an 8% absorption rate for NPK fertilizers. That makes their impact on any crop more immediate, with a stronger increase in productivity, and a long-term impact on improving the quality of the soil over time. It also means that this fertilizer only needs to be applied three times during the growing season. If a plant produces roughly 6 million gallons of Mineral-Gro® per year and 1 gallon treats one acre on average, and if each crop requires up to three applications per growing season, then the production of one wet plant using 6 turbines will successfully treat 2 million acres per year. This will result in the elimination of the need for other fertilizers, or a significant reduction in the need for and use of NPK, less water and lower levels of pesticides. This represents a higher and disproportionate impact on the amount of NPK required per acre (20 treatments/crop/200 lbs. per acre) when replaced by Mineral-Gro TNT using only 3 gallons per acre across 3 treatments per growing season.

c) Current or prospective end‐user commitments

Having demonstrated the cost benefit analysis of Mineral-Gro® as a legitimate, natural alternative to synthetic fertilizers, the Mineral-Gro® team is currently working with the larger agricultural producers to move from early adopters to full-scale adoption of this unique alternative as a foliar spray option to traditional NPK products.

Climate Impact and Sustainability

a) Expected type, scale, and longevity of direct benefits from greenhouse gas emission mitigation

Worldwide,”agriculture is the second-largest source of climate change pollution—and both the manufacturing and application of fertilizer has a heavy emissions toll. Synthetic nitrogen fertilizers (derived from fossil gas) and pesticides (derived from fossil gas and crude oil) both contribute to global warming, biodiversity collapse, and toxic pollution. From a manufacturing perspective, the production of the key component of synthetic nitrogen fertilizers is Ammonia (NH3)which contributes between 1 and 2% of worldwide carbon dioxide emissions. Ammonia has to be made at a high pressure under high temperatures—meaning it takes a lot of energy to manufacture. Most of that energy comes from burning fossil fuels like coal and methane gas, which give off the greenhouse gas carbon dioxide, the main cause of climate change.

From an application perspective, synthetic NPK fertilizers also produce greenhouse gases after farmers apply them to their fields. Crops only take up, on average, about half of the nitrogen they get from synthetic fertilizers. NPK fertilizer applied to crops release an estimated 450 million tons of carbon dioxide (CO2) per year as a result of only half of the fertilizer being absorbed by crops — equivalent to the total energy system emissions of South Africa. Much of the applied fertilizer runs off into waterways, or gets broken down by microbes in the soil, releasing the potent greenhouse gas nitrous oxide into the atmosphere. Although nitrous oxide accounts for only a small fraction of worldwide greenhouse gas emissions,pound for pound, nitrous oxide warms the planet 300 times as much as carbon dioxide.Agriculture accounts for roughly two-thirds of global emissions of nitrous oxide (N2O).

Mineral-Gro® climate safe, organic nano-sized fertilizer contains 78 trace minerals from its Montmorillonite deposits. There are two types of greenhouse gas emissions that will be mitigated through the production of Mineral-Gro® as an alternative climate safe and organic fertilizer. The first is the difference in emissions reduced during production of Mineral-Gro® vs. NPK, the second is the reduction in greenhouse emissions because significantly fewer applications are required for each crop, 3 applications for Mineral-Gro® vs. traditional NPK fertilizers and the higher absorption rate and lower amounts of nitrogen in Mineral-Gro® mean less nitrous oxide produced

b) Expected type, scale, and longevity of indirect benefits from greenhouse gas emission mitigation

Waste by-products are also an issue with NPK fertilizers. Nitrogen production

requires extensive use of water and fossil fuels for manufacturing. When used in

excess, nitrogen fertilizers can be oxidized and lost to the air as nitrous

oxide.Nitrous oxide is a long-lived greenhouse gas that contributes to

global warming. It stays in the atmosphere for an average of 114 years and is300

times more potent than carbon dioxide. Potassium and Phosphorus are

both mined ores. Phosphate production generates huge amounts of phosphogypsum

wastes, nearly 48 million MTs in 1988 alone. Industry estimates that 5.2 tons of

phosphogypsum is produced for every ton of phosphoric acid. Phosphorus processing

also produces high quantities of naturally occurring radioactive materials. The

environmental impact of potash mining is generally localized to the mine site, and

may include the disruption of vegetation and wildlife, as well as large-volume water

consumption and contamination. Then all three components (NPK) have to be processed

together. This quadruple production process has massive negative impacts on the

immediate environment and broader climate change impacts.

Mineral-Gro® has no byproducts, either during mining or processing. The deposits are

mined and 100% processed into micro-sized powder in the first step. During the

second step, the powder is nano-sized and concentrated in water. 95% of all water is

filtered and then used in the final product. The amount of water waste is negligible

and safe. The number of by-products of any kind is also negligible and safe.

The secondary indirect benefit of Mineral-Gro® is that it is applied to crops only

three times during a growing season at an average of 1 gallon per acre as compared

to 20 applications of NPK during a growing season, at 200 lbs. per acre. This

increased efficiency, reduces the need for the volume of product, dramatically

reduces the use and need for NPK at the level it is being used by producers today.

c) Other (non-greenhouse gas) environmental benefits

The dramatic increase in the use of synthetic fertilizers (NPK) since the early 1900’s has resulted in the depletion of naturally occurringminerals in soils.The Earth Summit concluded in 1992 that “There is deep concern over continuing major declines in the mineral values in farm and range soils throughout the world.” This was based on data showing a decline in nutrient levels over the last 100 years: Europe – 72% decline. Asia – 76% decline, North America – 85% decline. Nanotechnology has the potential to revolutionize the agricultural and food industry with new tools for the molecular treatment of diseases, rapid disease detection, enhancing the ability of plants to absorb nutrients etc. Mineral-Gro® restores the soil over time, increasing the biologics in the soil, adding back in a wide range of trace minerals, replaces or dramatically reduces the use of NPK, reducing the leeching from the soil that synthetic fertilizers cause.

PERFORMANCE METRICS

a) Provide agricultural producers with more domestic options for fertilizer and nutrient alternatives.

Mineral-Gro® is a climate safe alternative, can be applied as a foliar spray that is immediately absorbed and accessed at a cellular level through the surface/leaves of plants, that is less expensive, requires fewer applications, eliminates leeching and other harms to the soil, decreases the use of water and pesticides, decreases growing season and increases productivity of crop yields by up to 50%. These are all wins for agricultural producers. Getting uptake of a new product that can replace or dramatically reduce the volume of NPK needed, is a challenge.

Mineral-Gro® is a climate safe alternative, can be applied as a foliar spray that is immediately absorbed and accessed at a cellular level through the surface/leaves of plants, that is less expensive, requires fewer applications, eliminates leeching and other harms to the soil, decreases the use of water and pesticides, decreases growing season and increases productivity of crop yields by up to 50%. These are all wins for agricultural producers. Getting uptake of a new product that can replace or dramatically reduce the volume of NPK needed, is a challenge.

b) Reduce the impacts of climate change through the manufacturing and processing of or the use of sustainable, innovative, increased, and efficient fertilizer and nutrient alternatives production and use.

As described above, Mineral-Gro® is an exciting and innovative alternative to synthetic fertilizers. It has no harmful by-products produced during manufacturing; is much simpler and faster to manufacture than tradition NPK; requires only 3 applications per crop cycle; reduces greenhouse gases by reducing the production of nitrous oxide (300 times more harmful that carbon dioxide) from NPK use; and rebuilds the soil while producing healthier crops with more nutrients for consumption.

ENVIRONMENTAL REVIEW

Mineral-Gro®’ mineral deposits were created over millions of years by a fresh water, stratified sediment largely composed of a montmorillonite, a phyllosilicate – not “silica” and alternating layers of organic material and residual fulvic acid forming a colloidal sandwich Impregnated with a diverse smorgasbord of trace elements chelated to amino acids. (See attachment for the list of trace minerals). Bentonitesand other types of clay can contain overwhelming amounts of certain minerals like silica that could pose potential danger to the system. Montmorilloniteis purer with much less calcium and sodium and greater exchange capacities. Its ability to adsorb and absorb toxins makes it the most preferred species of edible clay. “Calcium-based clays are referred to as ‘living clays’ as they principally consist of minerals that contribute to the production of enzymes in all living organisms. They are the preferred clays to be ingested by humans, animals, and plants and for incorporating into soil.” http://www.aboutclay.com/history_of_clay.

Montmorillonite has demonstrated benefits for humans and animals. For plants, the benefits include: Increased yield, bigger plants, more blossoms = more fruit, larger fruit, longer growing season, higher protein count, better nutritional value, reduces wilting during heat and dehydration after harvest, thwarts fungus attacks, increases resistance to other parasites. The montmorillonite helps: foster pro-biotic life that can actually free up nutrients enhancing their bio-availability, break down toxins, turning them into usable elements later on, and bind nutrients to soil particles for easier absorption.

The v deposits provide the source of the climate-safe natural fertilizer patented as Mineral-Gro®. There are no harmful components in the inputs (montmorillonite) and no harmful by-products that result from the micronizing and nano-sizing of the deposits. The only environmental issue that anMineral-Gro® fertilizer production plant needs to address is the potential for mineral dust while the powder is being transferred into the turbines.

The end product is a concentrate of the minerals in water. 99% of all water used to make the concentrate is contained in the final product. The plant produces almost zero mineral product waste or water waste. And any waste produced is made up of safe, non-hazardous materials. As a result, the facility maintains a ventilation system and workers use N-95 filters while transferring mineral powder into turbines during production. The following citation from the EPA’s Identification and Listing of Hazardous Waste 40 CFR §261.4(b): Exclusions: Solid Wastes which are Not Hazardous Wastes.

§261.4(b)(7) Mining and Mineral Processing Wastes (Bevill)

(i) For purposes of Sec. 261.4(b)(7) beneficiation of ores and minerals is restricted to the following activities; crushing; grinding; washing; dissolution; crystallization; filtration; sorting;sizing; drying; sintering; pelletizing; briquetting; calcining to remove water and/or carbon dioxide; roasting, autoclaving, and/or chlorination in preparation for leaching (except where the roasting (and/or autoclaving and/or chlorination)/leaching sequence produces a final or intermediate product that does not undergo further beneficiation or processing); gravity concentration; magnetic separation; electrostatic separation; flotation; ion exchange; solvent extraction; electrowinning; precipitation; amalgamation; and heap, dump, vat, tank, and in situ leaching.

The Mineral-Gro® Climate Smart Fertilizer Plants will meet all environmental and OSHA requirements. Due to the safe and efficient nature of the production of Mineral-Gro®, there are no harmful waste by-products (either water or solid waste).

Contents of the MINERAL Gro/NPK75 fertilizer:

78 Trace Minerals that replenish the soil and improve the nutrition of crops produced.

| Name | Symbol | Atomic # |

|---|---|---|

| Aluminum | Al | 13 |

| Antimony | Sb | 51 |

| Arsenic | As | 33 |

| Barium | Ba | 56 |

| Beryllium | Be | 4 |

| Bismuth | Bi | 83 |

| Boron | B | 5 |

| Bromine | Br | 35 |

| Cadmium | Cd | 48 |

| Calcium | Ca | 20 |

| Carbon | C | 6 |

| Cerium | Ce | 58 |

| Cesium | Cs | 55 |

| Chlorine | Cl | 17 |

| Chromium | Cr | 24 |

| Cobalt | Co | 27 |

| Copper | Co | 29 |

| Dysprosium | Dy | 66 |

| Erbium | Er | 68 |

| Europium | Eu | 63 |

| Fluorine | F | 9 |

| Gadolinium | Gd | 64 |

| Gallium | Ga | 31 |

| Germanium | Ge | 32 |

| Gold | Au | 79 |

| Hafnium | Hf | 72 |

| Holmium | Ho | 67 |

| Hydrogen | H | 1 |

| Indium | In | 49 |

| Iodine | I | 53 |

| Iridium | Ir | 77 |

| Iron | Fe | 26 |

| Lanthanum | La | 57 |

| Lead | Pd | 82 |

| Lithium | Li | 3 |

| Lutetium | Lu | 71 |

| Magnesium | Mg | 12 |

| Manganese | mn | 25 |

| Mercury | Hg | 80 |

| Molybdenum | Mo | 42 |

| Name | Symbol | Atomic # |

|---|---|---|

| Neodymium | Nd | 60 |

| Nickel | Ni | 28 |

| Niobium | Nb | 41 |

| Nitrogen | N | 7 |

| Osmium | Os | 76 |

| Oxygen | o | 8 |

| Palladium | Pd | 46 |

| Phosphorus | P | 15 |

| Platinum | Pt | 78 |

| Potassium | K | 19 |

| Praseodymium | pr | 59 |

| Rhenium | Re | 75 |

| Rhodium | Rh | 45 |

| Rubidium | Rd | 37 |

| Ruthenium | Ru | 44 |

| Samarium | Sm | 62 |

| Scandium | Sc | 21 |

| Selenium | Se | 34 |

| Silicon | Si | 14 |

| Europium | Eu | 63 |

| Silver | Ag | 47 |

| Sodium | Na | 11 |

| Strontium | S3 | 38 |

| Sulphur | S | 16 |

| Tantalum | Ta | 73 |

| Tellurium | Te | 52 |

| Terbium | Tb | 65 |

| Thallium | Tl | 81 |

| Thorium | Th | 90 |

| Thulium | Im | 69 |

| Tin | Sn | 50 |

| Titanium | Ti | 22 |

| Iron | Fe | 26 |

| Tungsten | W | 74 |

| Uranium | U | 92 |

| Vanadium | V | 23 |

| Ytterbium | Yb | 70 |

| Yttrium | Y | 39 |

| Zinc | Zn | 30 | Zirconium | Zr | 40 |

What is Liquid TNT®?

When Liquid TNT® is mixed with water and applied as a foliar spray to leaves or added to the soil, up to 78 nano minerals become readily available to the plants. The amount of required water and pesticides are reduced and your plants will grow bigger, stronger, and healthier.

PROBLEM:-

The organic materials inoursoil that plants relyon Unlike most fertilizers,Liquid TNT" is a nutrient-rich spray that can also forgrowth aredecreasing

Fruitsand vegetables arebecoming less nutritious

Soil nutrient shortages will eventually cause When gardeners and farmers utilizeLiquid TNT".they're paving a dependency on nutrient richcountries

MINERAL-GRO SOLUTION:-

Unlike most fertilizers,Liquid TNT" is a nutrient-rich spray that can also forgrowth aredecreasing be directly applied at the root

Liquid TNT® contains allthe organic minerals your garden needs -once Fruitsand vegetables arebecoming less nutritious the parenchyma tissue and your soil areenriched with these organic fertilizerminerals,they will pass their life-giving energy into the plants and intoyour meal

When gardeners and farmers utilizeLiquid TNT".they're paving a dependency on nutrient richcountries healthy and independent pathway fortheir plants and crops

Patented Technology: Two Stage Process

Dry Stage

The minerals are blended in a vortex chamber using compressed air and

resonant frequencies for pulverization.

The minerals become micron-sized

dry powder

Wet Stage

The micronized minerals are sent through a patented Vortex Controlled

Hydrodynamic Cavitation process to implode and nano-size the minerals into a

liquid concentrate.

The resuit is "activates" water with nano-size

minerals

This final liquid concentrate is ready to mix with more water and applied asa foliar spray on the crops or plants.

Liquid TNT® , NPK75, Mineral Gro, Compared to Other Fertilizers

- Produced better Seed germination

- Improved root formation

- Facilitated plant growth and development

- Increased yields

- Improved product taste characteristics

- Inhibited bacterial and fungal diseases

- Reduced the level of heavy metal accumulations

- Reduced the level of radionuclide accumulations

- Increased drought resistance of plants

- Increased the cold resistance of plants

- Increased soil fertility

Products – Biomass Plant

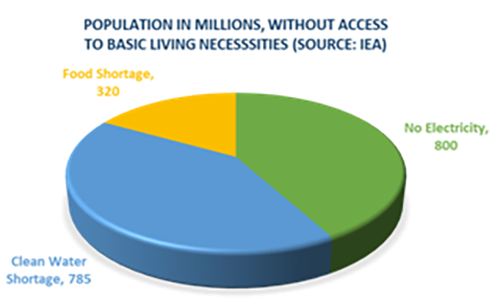

It’s Time to Help Solve These Global Challenges

Energy shortages around the world

- 800M people globally lacked access to electricity*

Clean water shortages around the world

- 785M people lack access to clean water**

Food shortage around the world

- 320M people across 92 countries in Crisis or Stressedconditions***

2020 World Energy Outlook – International Energy Agency

The Global Water Crisis – The World Economic Forum

2020 Global Report on Food Crisis – Global Network Against Food Crisis / Food Security Information Network

U.S. Farmers Challenges

U.S. Challenges are different from global challenge however the need and economics are compelling

- Cost to dispose of Biomass

- Changing regulations about using landfills

- Environment issues with composting

- Environmental issues with burning

- Other issues

- Smells, insects, ground water pollution

Our technology and projects change Biomass from an expense item to a profit center for the farmers

Our Holistic Solution

Veritasisa biomass to energy technologycompany that provides scalable and modular solutions for the global challenges of renewable energy, clean water and sustainable food.

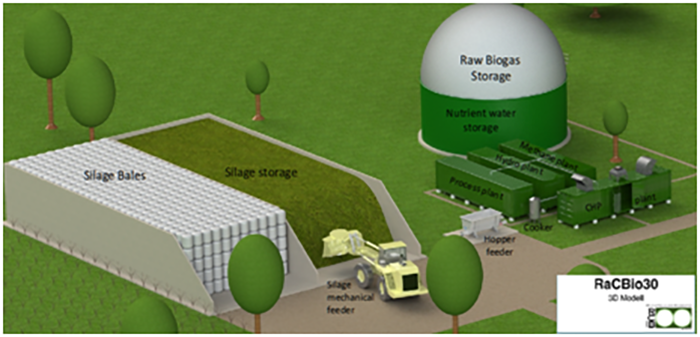

Veritas RaCBio (Rapid Cellulose Bio-Reactor)

- Convert Cellulose Rich Biomass

- 2G Patented Technology

- Biogas, Protein, Nutrient Water

PYREG (Mixed Waste Recycling)

- Pollutant-free Recycling Process

- BioChar, Carbon Credits

- Reduced CO2 Footprint for Centuries

BIO-4 (Wastewater Treatment)

- BIOCOS® - Active Sludge Technology

Renewable Energy

- Electricity

- Bio-Methane

- RNG (Renewable Natural Gas

- H2 (Hydrogen)

Protein Pellets – Animal Feed

Terra Preta Soil Enhancer

- Mixing Biochar, Protein, Nutrient Water

Carbon

- Activated Charcoal, Biochar

- Carbon Credits (RINs, LCFS & RECs

Portable Water

RaCBio versus Traditional AD Solutions

- Production time 3 days -vs- 30-50 days for AD

- Bio-Reactor “built-into” custom 40ft shipping containers

- Mass produced -vs- “on-site” plant construction

- 10 times smaller than for an AD plant

- 10-fold decrease in capital investment

- Operational in 3 months

Biomass to Energy Process

Patents and Intellectual Property

Patented technology in combination with intellectual property for commercializing processes and packages

Patented Technology

- Ruminant Simulation Technology (RuSiTec)

- Simulates the digestive system of a cow

- 2nd Generation (2G) bio-chemistry process

- iBert holds an exclusive right to use the RuSiTec patented process

iBert RCB - Intellectual Property

- Commercialization and Packages

- Feedstock production and processes

- Hydrolysis

- By-products “off take”

Technology Associates

Partnering with PYREG and BIO-4 enables Veritas to produce high quality by-products whileproviding a complete ”off-grid” ecosystem of sustainable power and clean water.

PYREG – Biomass to Carbon

- Biochar, Feeding Char or Activated Carbon

- Blend Biochar with Protein and Nutrient Water to create Terra Preta Soil Enhancer

- Carbon Credits

BIO-4 – Smart Water Solutions

- BIOCOS® Wastewater Purification

- Hybrid Active Sludge Technology

- Scalable for 50 to 1,000,000 people

Project #1 Model – Veritas & Farmers Partnership (SPV)

Equitas Assets and Farmer work as partners in plant operations, and sales and marketing of take-out products.

Establish Special Purpose Vehicle (SPV) Company

- Owns feedstock supply agreement

- Owns the Power Purchase Agreement (PPA)

- Owns energy and other by-product sales Executes lease agreement for turnkey plant

- Setup and deploy plantT

- Plant operationsT

- Manages take-out products including packaging and shippingT

- Fully operational in 3 monthsT

- Terms 20 yearsT

- Veritas and Farmers Split EBIT

Veritas Group

- Owns land for plant

- Performs sales and marketing for take-out products

Project #1

- 55 Acres in Northern California

- 2MW plant

- 2MW plant

- Plant Cost $46M

- Annual Revenue $60M+

- Operating Cost $5M

- EBIT $60M+

- Capacity of Plant / Location 10 Times the initial build